I was the main EE on a Vivint camera project while it was still under development. Here are some of the things I did for this project.

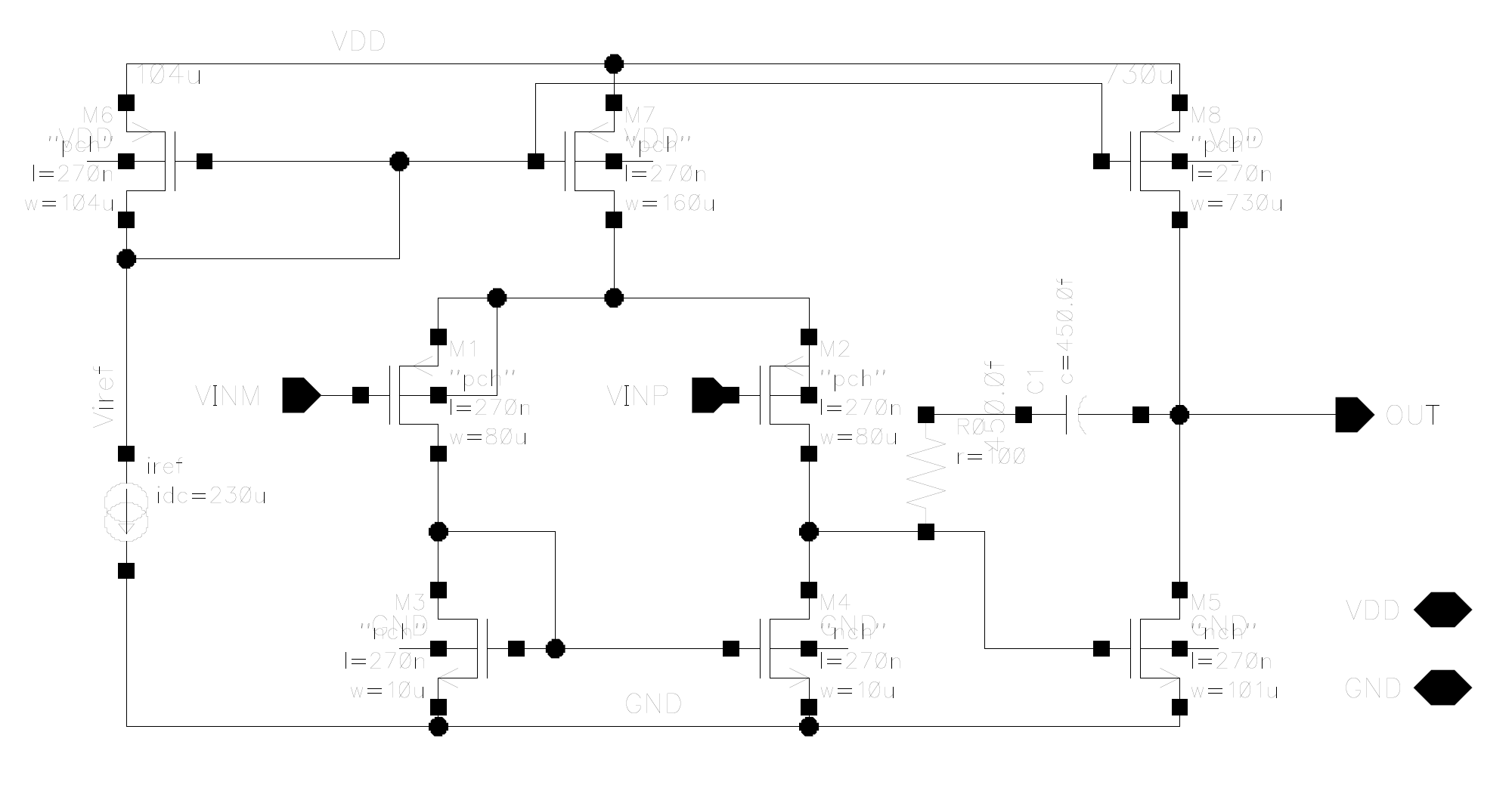

I wrote & implemented the test plan for the first PoC of the product. This included evaluating the efficiency of the entire power tree of the device. In order to reduce the power consumption to improve the thermals, I redesigned much of the power tree to be more efficient, and used simulation tools (LTspice, etc) to check the improvements. These changes should take over 1W out of the system, which is a big deal for a product like this!

At Vivint, we partnered with a third party company in Taiwan to jointly develop the product. I had to communicate and work remotely with this team in order to get the design we want. This involved much back & forth communication with plenty of documentation for both the schematic and layout of the board. The layout in particular I give a lot of feedback on to ensure that the product will have high signal integrity, low emissions, and good power delivery. Through Vivint, attended a two-day course called “PCB2Day” in order to learn the essentials of good PCB design.

The electronics of the product do not operate withing a vacuum. I’ve had to work closely with the firmware engineers, mechanical engineers, and industrial designers on the project to make sure all the pieces come together to create a good product.